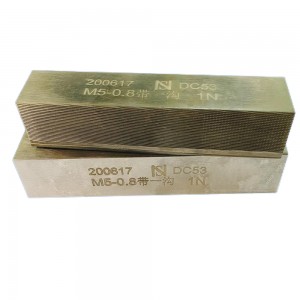

Carbide Threading Dies Thread Roller Dies

Our thread rolling flat dies are manufactured to JIS grade standards and are designed to provide superior performance and durability. Careful design and production processes ensure that our molds meet the highest quality standards, making them reliable tools for thread rolling operations.

The thread rolling process using our dies is efficient and seamless. By using a push tool, the workpiece is inserted between the flat dies and the thread is formed in a single working stroke. This streamlined process not only increases productivity but also ensures consistent and accurate threading results.

| Item | Parameter |

| Place of Origin | Guangdong,China |

| Brand Name | Nisun |

| Material | DC53, SKH-9 |

| Tolerance: | 0.001mm |

| Hardness: | Generally HRC 62-66, depends on material |

| Used for | tapping screws,Machine Screws,Wood Screws,Hi-Lo Screws,Concrete Screws,Drywall Screws and so on |

| Finish: | Highly mirror polished finish 6-8 micro. |

| Packing | PP+Small Box and Carton |

The regular maintenance of mold parts has a great influence on the life of the mold.

The question is: How do we maintain when using these components?

Step 1.Make sure there is a vacuum machine that automatically removes the waste at regular intervals. If the waste is removed well, the breakage rate of the punch will be lower.

Step 2.Make sure the density of the oil is correct,not too sticky or diluted.

Step 3. If there is a wear problem on the die and die edge, stop using it and polish it in time, otherwise it will wear out and quickly expand the die edge and reduce the life of the die and parts.

Step 4. To ensure the life of the mold, the spring should also be replaced regularly to prevent the spring from being damaged and affecting the use of the mold.

1.Drawings Confirmation----We get drawings or samples from customer.

2.Quotation----We will quote according to customer's drawings.

3.Making Molds/Patterns----We will make molds or patterns upon customer's mold orders.

4.Making Samples---We will use the mold to make the actual sample, and then send it to the customer for confirmation.

5.Mass Production----We will make bulk production after getting the customer's confirmation and order.

6.Production inspection----We will inspect the products by our inspectors, or let customers inspect them with us after completion.

7.Shipment---- We will ship the goods to the customer after the inspection result is OK and confirmed by customer.