News

-

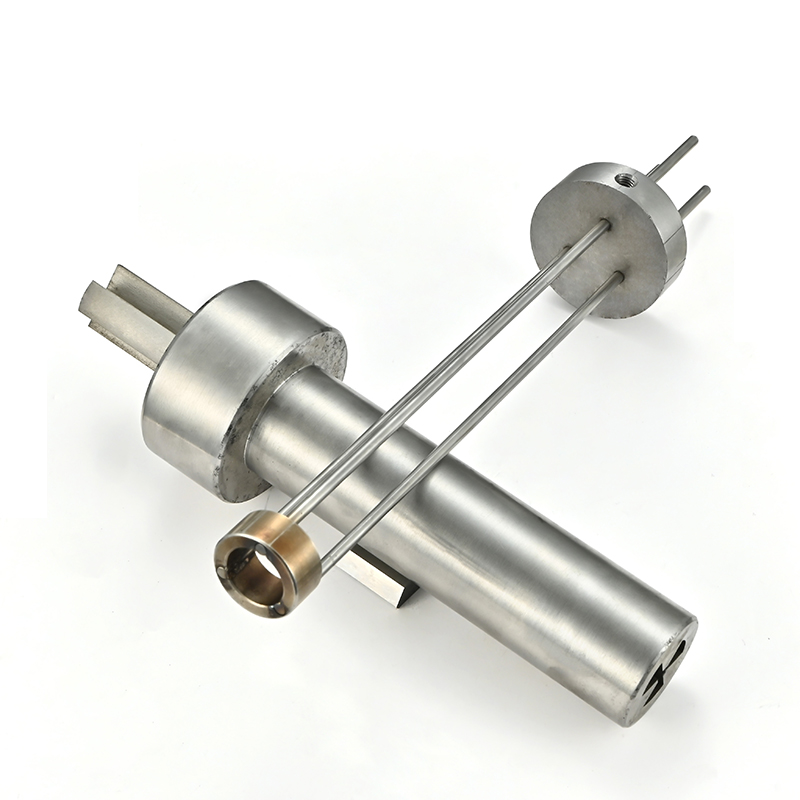

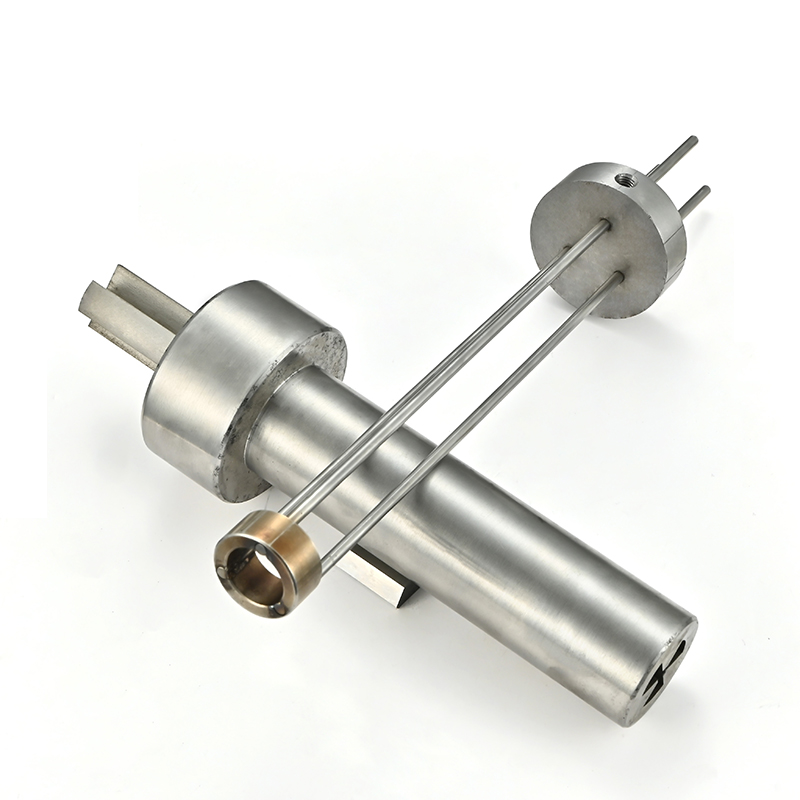

How does die punching work?

Die punching is a key process in manufacturing, used to create precise and complex shapes in a variety of materials. It involves using dies and punches to cut, shape or form materials such as metal, plastic, paper and fabric. A die is a specialized tool used to shape or ...Read more -

What is the difference between a punches and die?

Punch and Die: Understanding the Differences Punch and die are important tools in the manufacturing and metalworking industries. They are commonly used in processes such as stamping, forging and forming to create precise shapes and holes in a variety of materials. While ...Read more -

What material is used to make punches?

Carbide punches are essential tools in various industries including manufacturing, metalworking, and construction. These punches are used to punch, punch or mark holes in a variety of materials including metal, plastic and wood. One of the key factors that affects the ef...Read more -

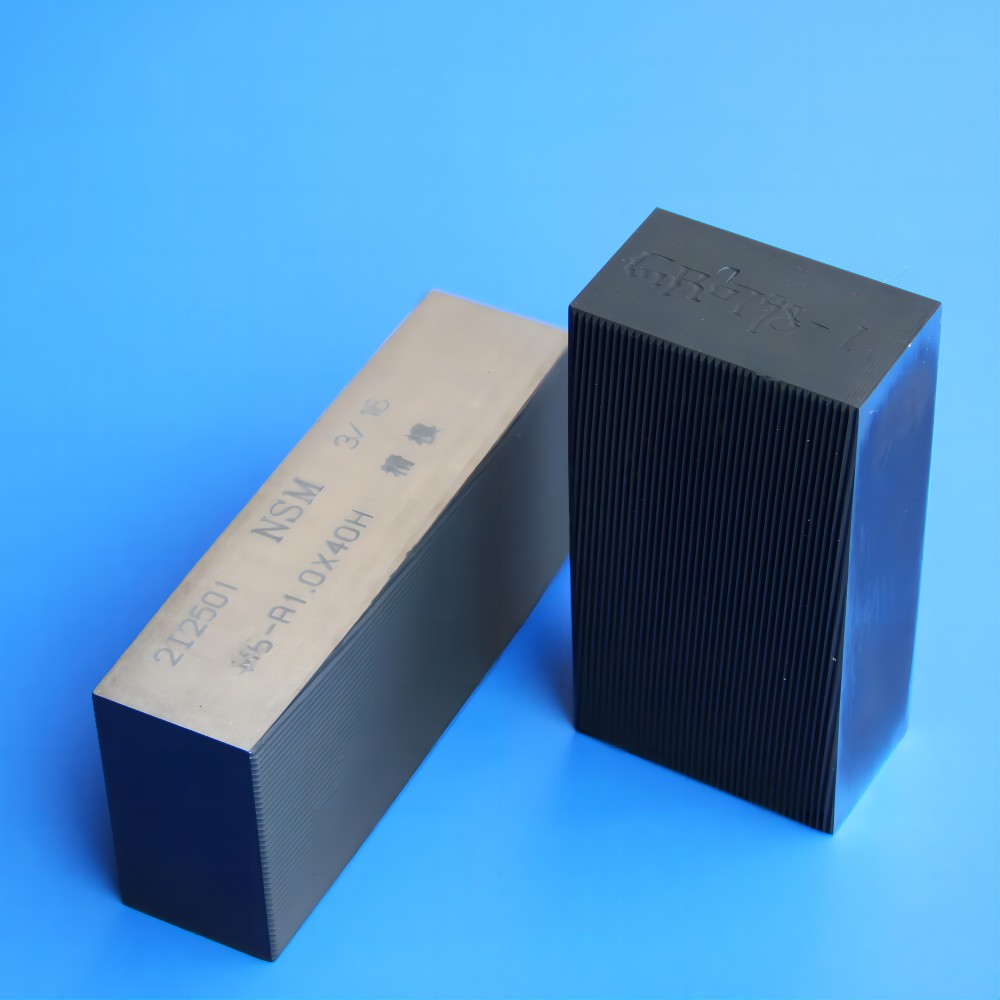

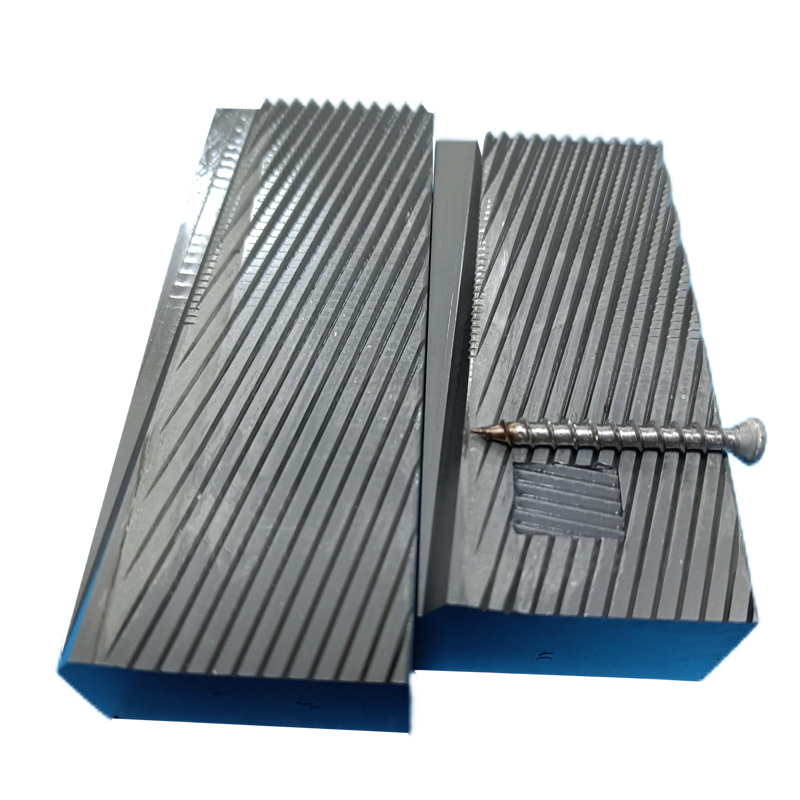

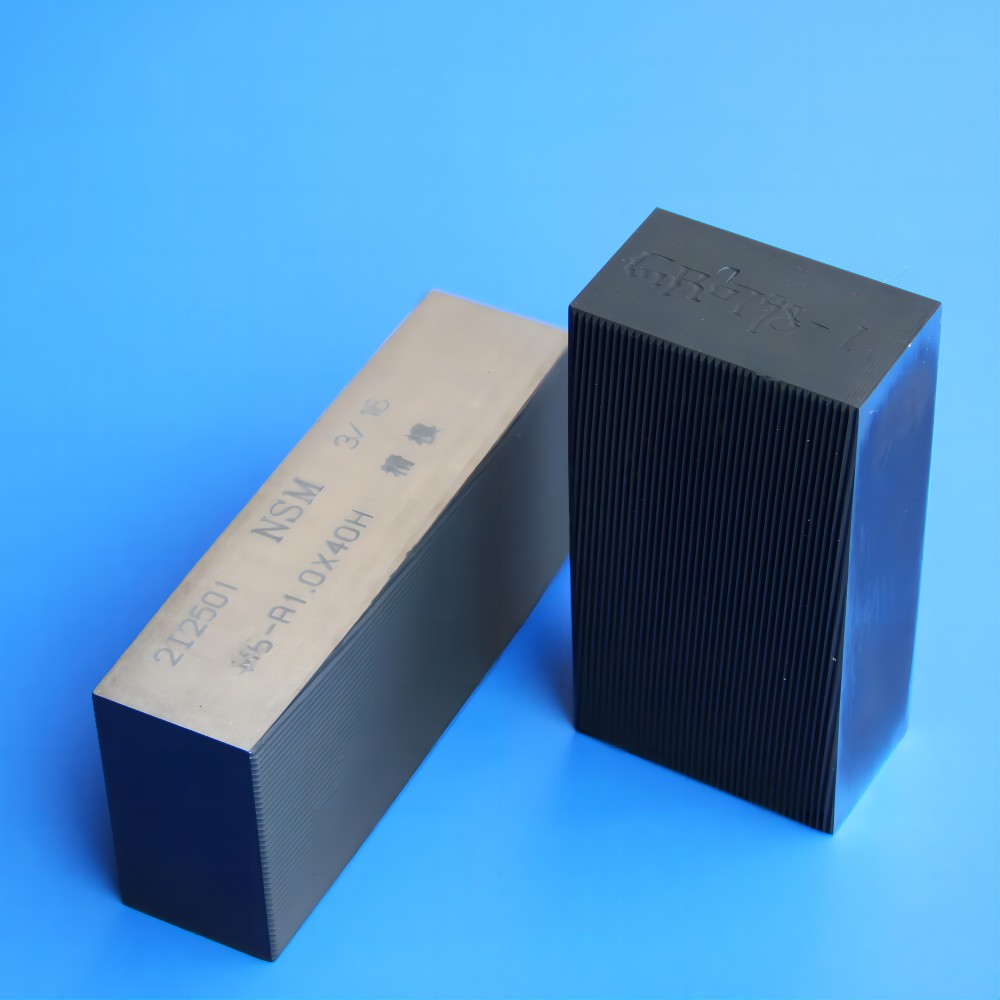

What is the best material for thread rolling dies?

Thread rolling dies are important tools in the manufacturing industry for processing threads on workpieces. These dies are designed to deform the workpiece material to create the desired thread profile. The material used in thread rolling dies plays a vital role in dete...Read more -

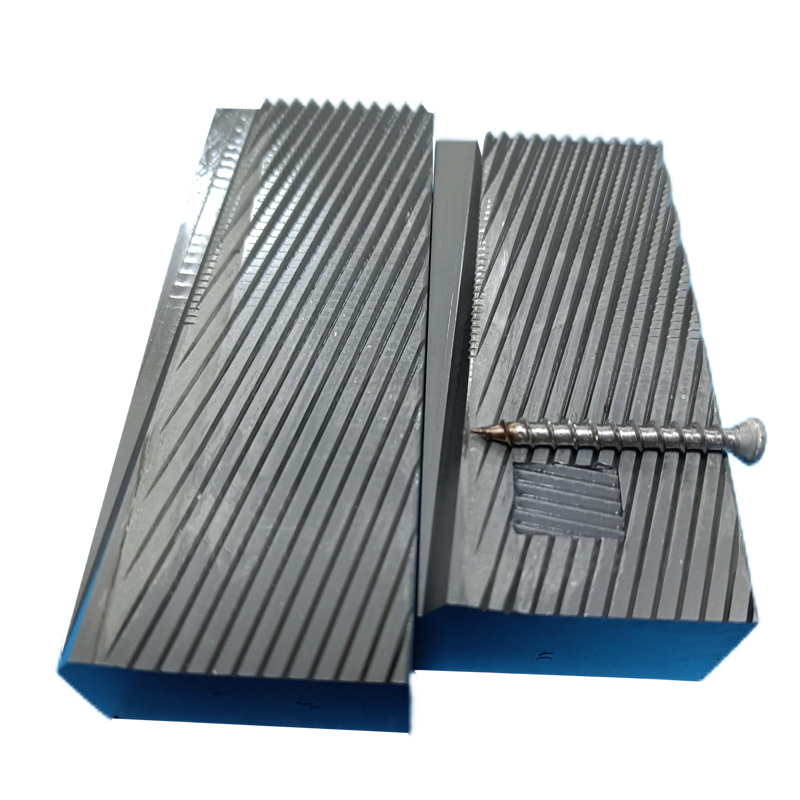

The Art of Precision: Nisun’s Thread Rolling Dies

At Nisun, precision is more than a goal; It's a way of life. Nisun specializes in the production of high-quality thread rolling dies and has become a leading manufacturer in China. The company's commitment to excellence and ability to meet the unique needs of the market ...Read more -

What is the use of tungsten carbide die?

Tungsten carbide dies are an important part of the manufacturing industry, especially in the production of various metal and plastic products. These molds are widely used to produce fasteners, wires, tubes, and other components that require precision molding and shaping...Read more -

What is the use of hexagonal molds?

A hex die is an essential tool in your tool box when it comes to repairing rusted or worn threads. Hexagonal dies, also known as hexagonal dies, are designed to clean and repair damaged threads on bolts, screws, and other fasteners. The die's hexagonal shape allows it to...Read more -

What is the advantage of thread rolling?

Thread rolling is a widely used manufacturing process that creates strong, precise and high-quality threads on a variety of materials. This process is made possible thanks to thread rolling dies, which are tools used to shape and form threads. These dies are designed and...Read more -

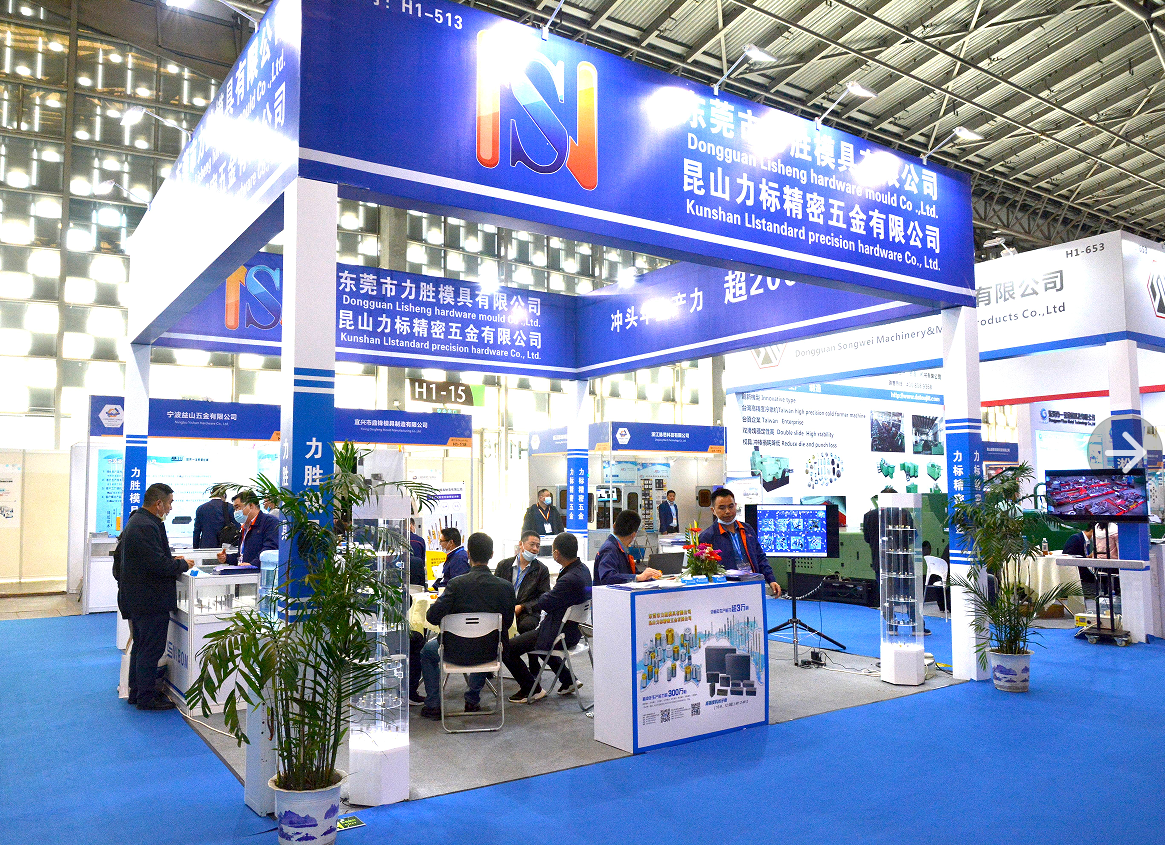

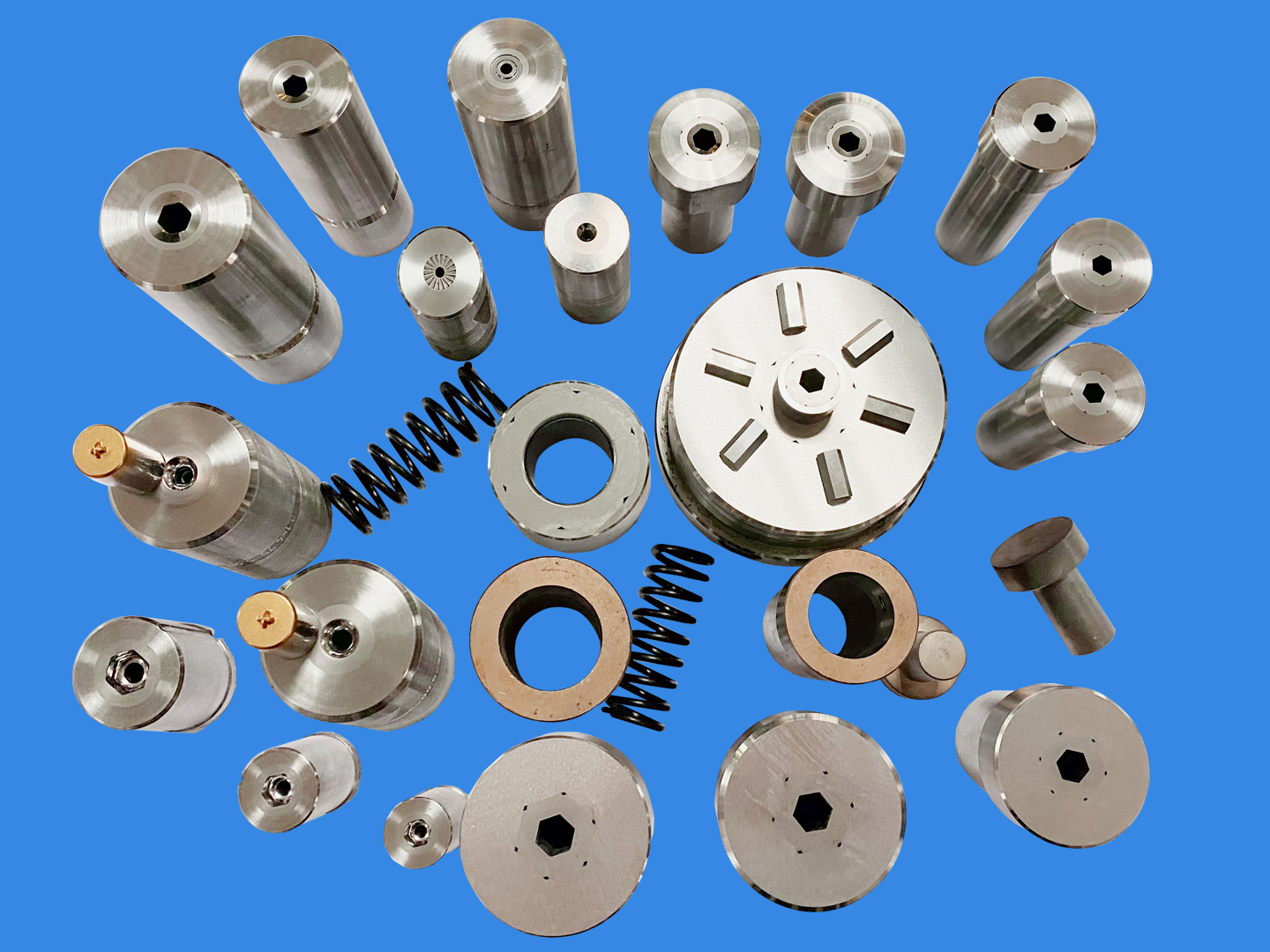

Nisun Mould Fastener Expo Shanghai 2023

In May 2023, the Fastener Expo Shanghai Exhibition was held as scheduled at the Shanghai World Expo Hall. Dongguan Nisun mould Co .,Ltd was invited to participate in the exhibition. During the exhibition, Nisun mould displayed its own punches, thread rolling die and carb...Read more -

What is a tungsten carbide drawing die?

Carbide mold versatility in manufacturing Carbide molds are essential tools in the manufacturing industry and are used to shape and form various materials such as metals and plastics. One of the most common types of carbide molds is carbide wire drawing dies, which are w...Read more -

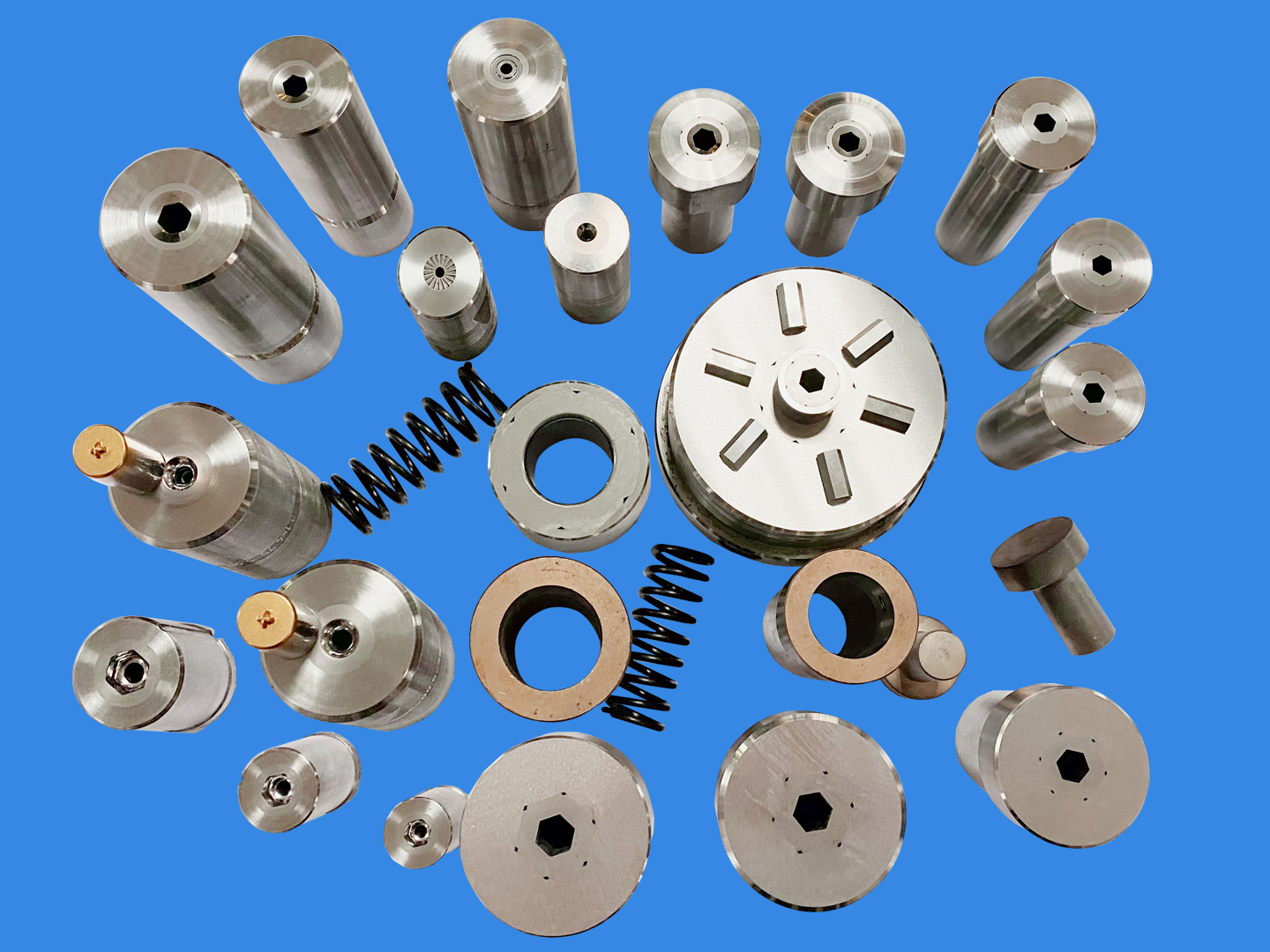

What are dies and punches?

In manufacturing and metalworking processes, dies and punches play a vital role in shaping and shaping materials. These tools are used in a variety of industries, including automotive, aerospace, and electrical. Tooling and punches are critical to manufacturing precisio...Read more -

How thread rolling dies are made?

The thread rolling die is an important tool used in the thread rolling process. They play a vital role in thread forming and shaping of a variety of materials, including metals and plastics. In this article, we will explore the intricacies of thread rolling die manufact...Read more