-

Carbide Tap And Thread Die Set

Thread rolling dies are tools used in the thread rolling process, a cold forming operation that creates external threads on a cylindrical workpiece. Thread rolling dies contain an inverted image of the thread profile that needs to be formed on the workpiece.

-

Carbide Threading Dies Manufacturers

The best materials for thread rolling dies are usually high speed steel (HSS) or carbide. High-speed steel is known for its high hardness, wear resistance and toughness, making it suitable to withstand the high pressures and stresses during thread rolling. On the other hand, has excellent hardness and wear resistance, making it a popular choice for thread rolling dies.

-

Taps And Dies For Threading Metal

Our thread rolling die systems are designed to be extremely efficient. We understand the need for speed and efficiency in modern manufacturing, which is why our systems are engineered to streamline the thread production process.

This not only helps increase productivity but also enables our customers to meet tight deadlines and production targets with ease.

-

Thread Rolling Dies Manufacturers

At Nisun we are proud to offer a range of high quality thread rolling die systems designed to meet the demands of modern manufacturing processes. Our systems provide a reliable and consistent method of thread production, making them ideal for numerous industries including automotive, aerospace, construction and more.

-

Thread Rolling Die for Making Fasteners

Our thread rolling die systems are designed to meet the demands of modern manufacturing processes, providing a reliable and consistent method for thread production. Whether it’s automotive, aerospace, construction or any other industry that requires high-quality threaded components, our systems deliver superior results.

-

Thread Rolling Dies Screw Rolling Machine

Our thread rolling die systems are simple and efficient to operate. Place the blank on one end of the stationary mold, and then move the mold to slide over the blank. This action causes the blank to roll off the fixed lower die in its finished form, with perfectly formed threads. Versatile and adaptable, our systems are available in a variety of thread forms, including ANSI, BS, DIN and JIS, to meet a wide range of industry needs.

-

Thread Rolling Die For Screw

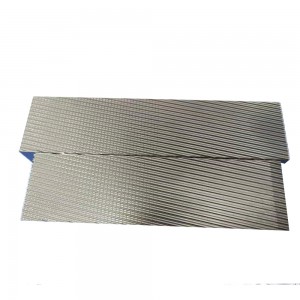

At Nisun Flat Dies, we pride ourselves on using only the finest materials in our products. Our flat dies are manufactured from high-quality steel, ensuring superior durability and performance. The use of fully tempered and hardened steel with the correct grain structure guarantees the longevity and reliability of our molds, making them ideal for precision thread forming applications.

-

Adjustable Hex Threading Dies

We understand the importance of precision and reliability in threading, which is why our thread rolling dies are crafted with attention to detail and quality. Whether you are in automotive, aerospace or manufacturing, our molds are designed to meet the needs of a variety of applications, providing smooth, efficient thread rolling capabilities.

-

Carbide Threading Dies Thread Roller Dies

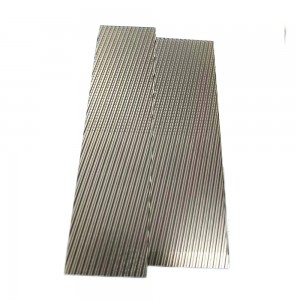

Our thread rolling flat dies are manufactured to JIS grade standards and are designed to provide superior performance and durability. Careful design and production processes ensure that our molds meet the highest quality standards, making them reliable tools for thread rolling operations.

-

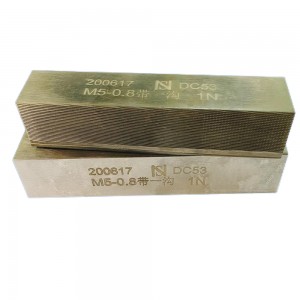

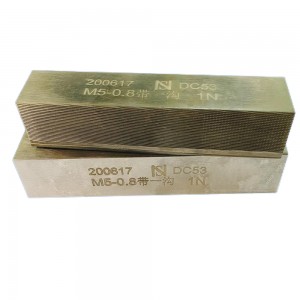

M5-0.8 Screw Planetary Thread Rolling Dies

What sets our thread rolling dies apart from the competition is the flat thread design, which provides a more streamlined and uniform threading process. This gives the screws a consistent and precise thread pattern, ensuring a safe and secure installation every time. Additionally, our molds are manufactured from high-quality, wear-resistant materials, guaranteeing long service life and cost-effective solutions for our customers.

-

Pineapple Flower P0.7 Thread Rolling Dies

Place of Origin:Dongguan, China

Brand Name:Nisun

Model Number:P0.7

Shaping Mode:Extrusion Mould,Preform Mould, Punching Mold

Product Material:VA80,VA90, KG6, KG5, ST7, ST6,CARBIDE

Size:003/0#/004/ 3/16/6R or according to client’s requirement

Product:Extrusion Mould

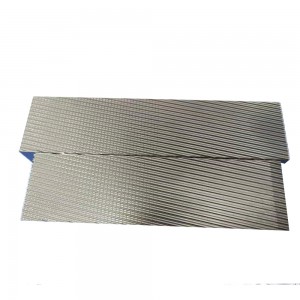

Product Name:Flat Thread rolling Dies

package:depends on request

Keyword:flat Thread rolling Dies

Application:For making screws thread

Package:Carton Package

Certificated:ISO9001:2015

-

Chamfering Light Nail Edentulous Thread Rolling Dies Plates

Features of Thread Rolling Tool/Roller/Dies/Mould/Mold

High output capacity with lower noise

No limit with processing length

Manufacture sophisticated, maintenance easily

Adjustable forming speed by invter

-

Phone

-

E-mail

-

Top